Why Shoot ECN-2 Film Instead of C-41

What it gives you, what it demands, and when it is the right choice

ECN-2 is a cinematographic colour negative process. It was engineered for motion-picture production environments where lighting is controlled, exposure is deliberate, and contrast and colour are shaped downstream rather than imposed at capture. The negative is expected to survive grading, manipulation, and repetition without collapse. That requirement defines everything about how ECN-2 behaves.

The correct question is not whether ECN-2 looks better than C-41. The correct question is why a photographer would choose a negative that deliberately withholds contrast and colour decisions, and what that choice enables.

ECN-2 does not reward unstructured use. It rewards intention. Photographers who choose it are not looking for chemistry to compensate for lighting or exposure decisions. They are choosing a system that assumes those decisions have already been made deliberately.

Kodak Vision3 250D technical data describing an emulsion engineered for motion-picture workflows, where exposure latitude, grading headroom, and downstream control take priority over immediate visual completion.

What ECN-2 is actually designed for

Some still films originate directly from motion-picture negative emulsions, most notably those derived from Kodak’s Vision3 family. These emulsions are designed from the outset to be processed in ECN-2 chemistry. Their colour couplers, contrast behaviour, and exposure latitude assume the ECN-2 process as a baseline condition rather than an alternative.

ECN-2 film has become visible to still photographers at exactly the wrong point in its workflow: after exposure, when expectations are shaped by C-41. When judged through that lens, ECN-2 is often described as flat, muted, or unfinished. Those descriptions are accurate in a narrow, descriptive sense, but they misunderstand the purpose of the film entirely. ECN-2 is not designed to deliver a finished image at the development stage. It is designed to preserve decision-making authority for later.

For still photographers, this means ECN-2 should be understood as a capture medium that prioritises latitude and predictability over immediacy. It is not meant to look complete straight out of development. It is meant to remain open, neutral, and information-dense so that contrast and colour can be shaped intentionally later.

This single design choice explains nearly every visible difference between ECN-2 and C-41.

Who should choose ECN-2, and who should not

ECN-2 is well suited to photographers working with directional, controlled lighting rather than broad, corrective illumination. It’s designed for motion picture sets, cinematographers and lighting crews that push its latitude limits. It favours projects built as cohesive bodies of work rather than isolated images. For stills it performs particularly well in professional portraiture where tonal continuity and skin integrity matter more than saturation and instant impact. It suits photographers who think in terms of tonal architecture, not just exposure.

In casual shooting, uncontrolled environments and workflows that expect a visually complete result immediately after processing, ECN-2 film will need more work. In those contexts, C-41 remains the more appropriate system because it is designed to compensate for variation and deliver a finished look with minimal intervention.

This distinction matters because ECN-2 is not better by default. It is chosen because it behaves differently under control. Control replaces correction. Latitude replaces baked contrast. Scanning becomes authorship rather than rescue.

Why ECN-2 looks flatter than C-41, and why that matters

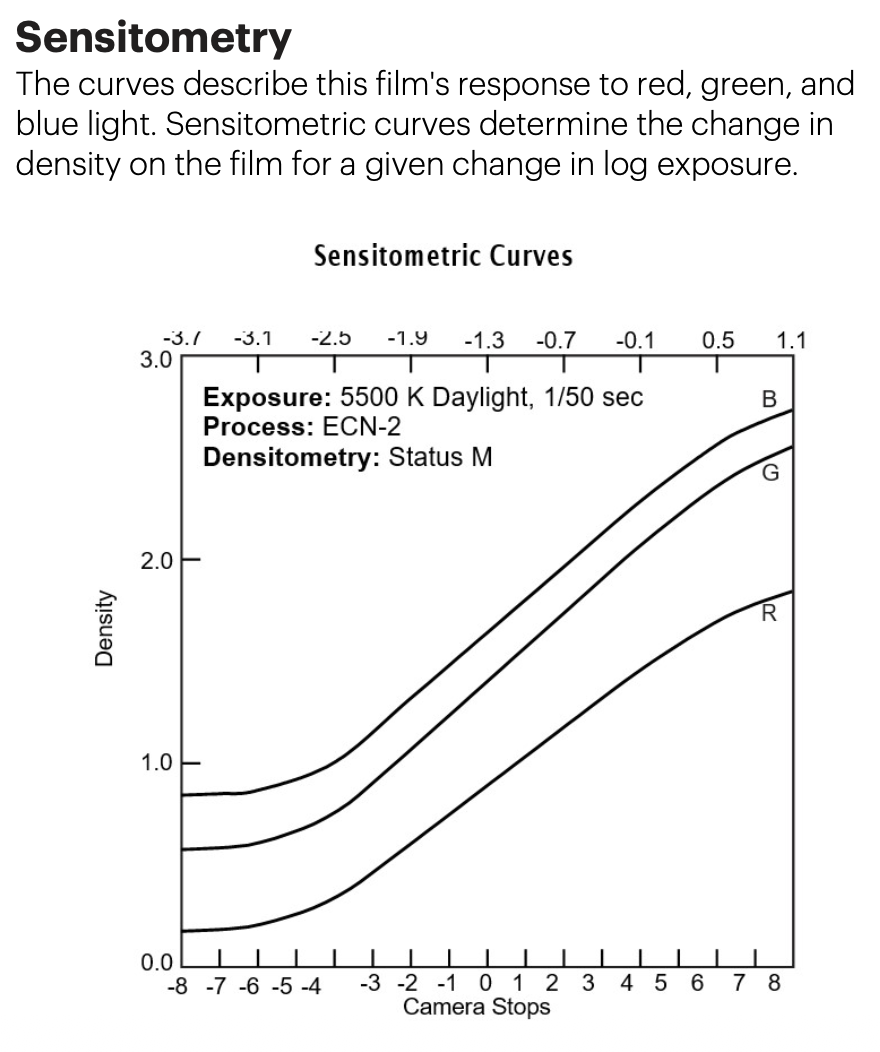

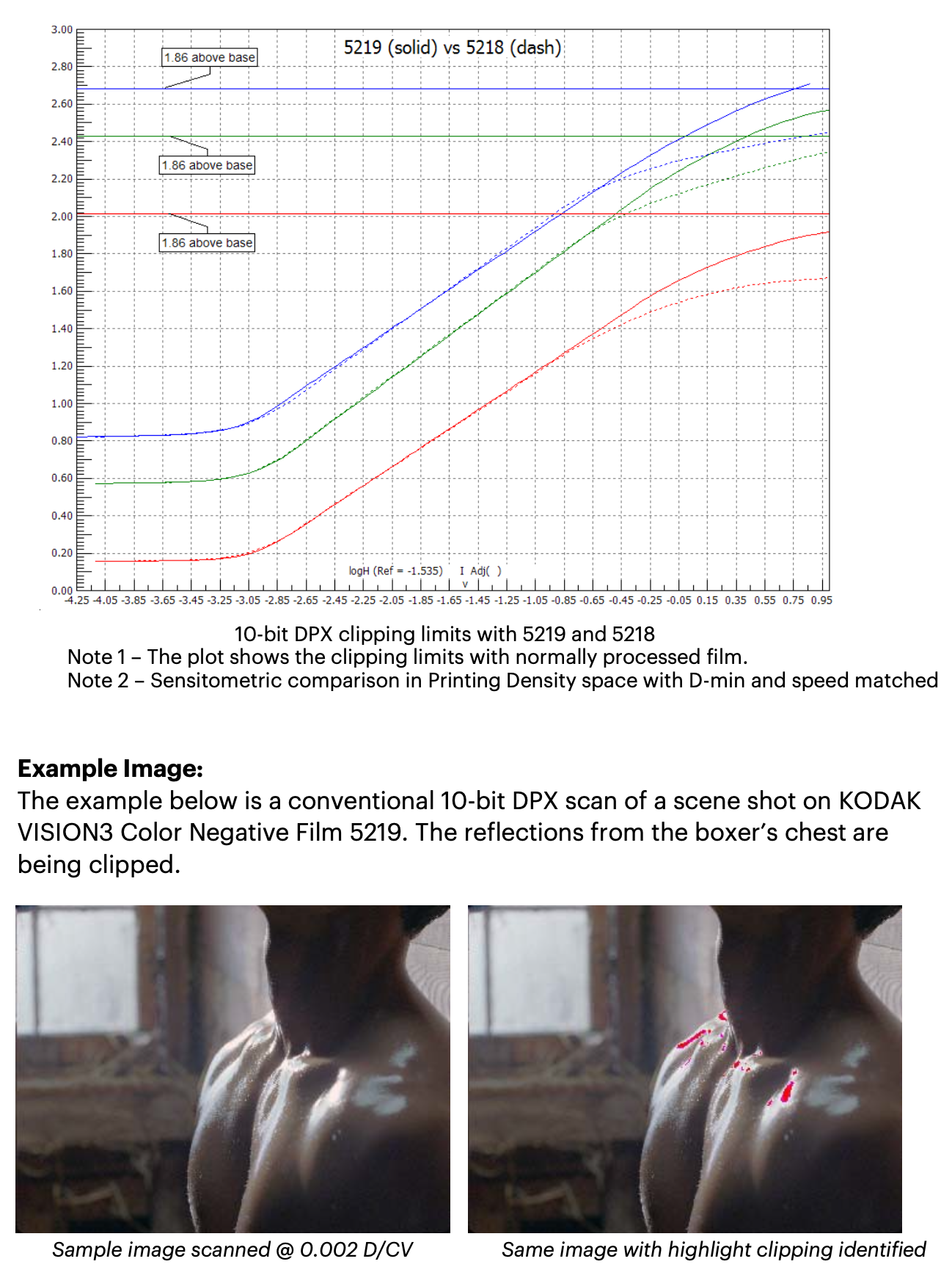

Sensitometric curves for a Vision3-derived ECN-2 colour negative, plotted in logarithmic exposure. This is a film-side measurement of density response, not a digital log encoding curve, but the shared logarithmic behaviour explains why ECN-2 appears flat and retains grading headroom when exposed and scanned correctly.

ECN-2 negatives are engineered for low native contrast. This is not a flaw or a stylistic quirk. It is a functional requirement. The emulsion stack prioritises colour separation and exposure latitude so that tonal and colour decisions can be made later without penalty.

When viewed without context, this produces negatives and scans that appear flatter than C-41 equivalents. What is missing is not information but imposed contrast. Density placement at exposure becomes critical because the system will not normalise the image for you. Highlights are held deliberately, shadows retain separation, and midtones remain open.

ECN-2 films are designed to be exposed at their rated exposure index, with highlight placement chosen deliberately rather than softened by routine overexposure as is common in C-41 workflows.

C-41 operates on a different assumption. It is engineered for direct optical printing and automated minilab workflows. Its contrast curve and colour balance are designed to produce a visually complete image quickly and consistently. Many tonal decisions are effectively made by the system before the photographer ever sees the negative.

A concise way to understand the difference is this: C-41 assumes the negative should compensate for exposure and lighting variation. ECN-2 assumes the photographer will not need that compensation.

What ECN-2 gives you in practical photographic terms

When used as intended, ECN-2 offers extended highlight retention with gentler shoulder behaviour. This allows bright areas to be shaped rather than clipped, particularly under hard or directional lighting. Shadow detail remains separated without being forced open by chemistry. Mid tones carry less baked-in saturation, which preserves skin tones and colour relationships that can otherwise collapse under heavy contrast.

The result is not a look but a working state. ECN-2 gives the photographer room to decide where contrast enters the image, whether through lighting ratios at exposure, development choices, or scanning and printing decisions later.

This is why ECN-2 is attractive to photographers producing series-based work. It prioritises consistency and control across multiple frames rather than punch in a single image.

Physical negative construction and why it matters

One of the less discussed but highly significant differences between ECN-2 and C-41 film is the physical base material. Motion-picture colour negative film is manufactured on a polyester base rather than the acetate base historically common in still photography.

Polyester offers substantially greater dimensional stability under heat and tension. In practical terms, this means the negative resists stretching, remains flatter, and maintains registration more consistently during handling and high-resolution scanning. Tear resistance is higher, reducing the risk of mechanical damage during processing and long-term use.

This material choice is not incidental. It is a requirement for a negative expected to pass repeatedly through mechanical systems without deformation.

Longevity and archival reality

Polyester base does not suffer from the same hydrolysis-driven degradation pathways associated with acetate, and there is no equivalent failure mode to vinegar syndrome. However, this advantage is conditional. ECN-2 longevity depends on complete rem-jet removal, proper fixing, thorough washing, and correct stabilisation.

Residual rem-jet can trap contaminants. Incomplete fixing compromises image stability. Incorrect stabilisation undermines long-term handling integrity. When ECN-2 is processed correctly, its archival characteristics are excellent. When it is not, the material advantages are lost. The system is robust, but it is not forgiving.

Kodak technical documentation stating that Vision3 motion-picture colour negative films are designed to be processed in ECN-2. This defines ECN-2 as the native chemical process for these emulsions, not an optional alternative.

Cinema-derived still films and chemical compatibility

Some still films originate directly from motion-picture negative emulsions. The most significant of these are derived from Kodak’s Vision3 colour negative family. This matters because Vision3 is not a look or a brand category; it is an emulsion system designed from the outset to operate within the ECN-2 process.

Vision3 emulsions are engineered with the assumption that ECN-2 chemistry is the baseline condition. Their colour couplers, contrast behaviour, and exposure latitude are specified to produce a low-contrast, information-dense negative intended for downstream grading rather than immediate delivery. This design intent is visible in Kodak’s own sensitometric data, which shows extended straight-line response, gentle shoulder behaviour, and colour separation that remains stable deeper into exposure.

When still films derived from Vision3 emulsions are processed in ECN-2, the result is the negative the emulsion was engineered to produce. Density placement, colour balance, and highlight behaviour align with the design assumptions of the stock. When the same emulsions are processed in C-41 chemistry, an image is produced, but it is no longer the designed negative. Contrast curves are altered, colour balance shifts, and shadow separation is often compromised because the chemistry resolves contrast earlier than the emulsion expects.

This distinction is important because it reframes the processing decision away from preference and toward compatibility. C-41 does not fail in an absolute sense, but it changes the behaviour of a Vision3-derived emulsion in predictable ways. ECN-2 preserves it. The choice is therefore not aesthetic but structural.

Understanding Vision3’s role clarifies why ECN-2 behaves differently from C-41 in practice. The process exists because the emulsion family exists. Treating ECN-2 as an optional alternative rather than as the native process for Vision3-derived films reverses that relationship and leads to misunderstanding of both.

Rem-jet is not a nuisance, it is part of the system

Rem-jet is frequently described as an inconvenience. In reality, it is a functional layer integral to the behaviour of ECN-2 film. It provides anti-halation control, preventing light from reflecting back into the emulsion and contaminating highlights. It protects the film base during transport through cameras and processing machinery. It contributes to cleaner highlight behaviour by suppressing internal reflections.

In practical photographic terms, rem-jet results in smoother highlight transitions and reduced halation around specular sources. This is one reason ECN-2 handles hard, directional lighting without the glow or bloom often associated with still-film highlights under similar conditions.

Treating rem-jet as a problem misses its role as an engineered component of the negative.

Bleach bypass and why ECN-2 supports it properly

Bleach bypass reveals another fundamental difference between ECN-2 and C-41. ECN-2 bleach chemistry allows controlled retention of metallic silver within the colour negative. This enables bleach bypass to function as a structural contrast tool, increasing density and altering tonal relationships while preserving colour integrity.

C-41 bleach and fix stages are designed to remove silver completely. Attempting bleach bypass within that architecture produces partial, inconsistent, or destructive results. The difference is not procedural but chemical. ECN-2 accommodates silver retention by design. C-41 does not.

This positions bleach bypass in ECN-2 not as an effect layered onto an image, but as an option embedded within the system itself.

Why scanning determines whether ECN-2 succeeds or fails

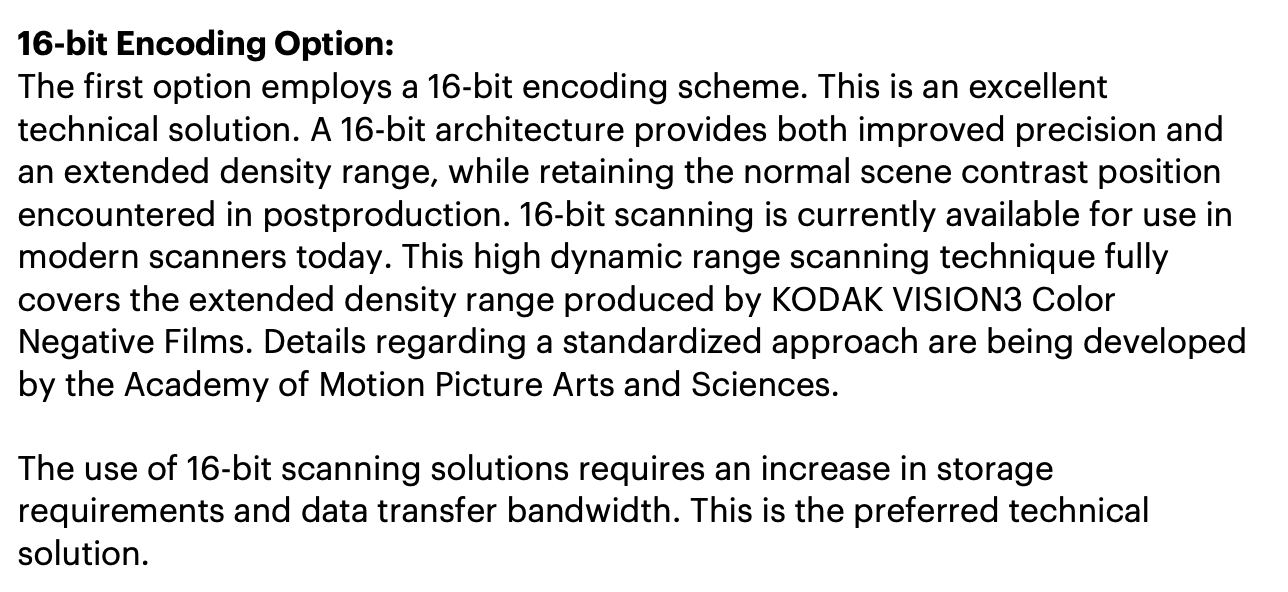

Kodak’s own scanning guidance identifying 16-bit encoding as the preferred technical solution for digitising Vision3 motion-picture negatives, as it preserves the full density range the film is designed to capture.

All of ECN-2’s advantages converge at the scanning stage. ECN-2 negatives exhibit wide density range and low native contrast. Scanning them correctly requires exposure control at the scanner, respect for colour separation, and density-aware inversion.

Automated or normalised scanning workflows, designed to force negatives into a predefined visual template, undermine the very characteristics ECN-2 is designed to preserve. An ECN-2 negative that has been normalised by automated scanning has not been completed; it has been overridden.

When ECN-2 scans appear thin or colour-unstable, the cause is almost always scanning, not exposure or development.

Kodak technical analysis showing how standard 10-bit DPX scanning clips highlight density in Vision3 motion-picture negatives. The film retains the information; the loss occurs when the scan cannot encode the full density range. 16bit is the technically correct solution.

Process tolerance and why ECN-2 exposes incompetence

ECN-2 operates within narrower tolerance windows than C-41. Temperature control, agitation consistency, rem-jet removal, bleach timing, and washing all have visible consequences. Errors present clearly as colour crossover, density loss, retained artefacts, or compromised highlight behaviour.

When ECN-2 negatives are correct, that correctness is not ambiguous. It reflects process control across development and scanning, not luck. This also explains why many labs avoid ECN-2 altogether. The additional steps, cleaning overhead, contamination risk, and incompatibility with automated minilab systems make it unattractive in volume-oriented environments.

Avoidance is not a judgement on ECN-2. It is a rational response to a system that demands time, control, and technical literacy.

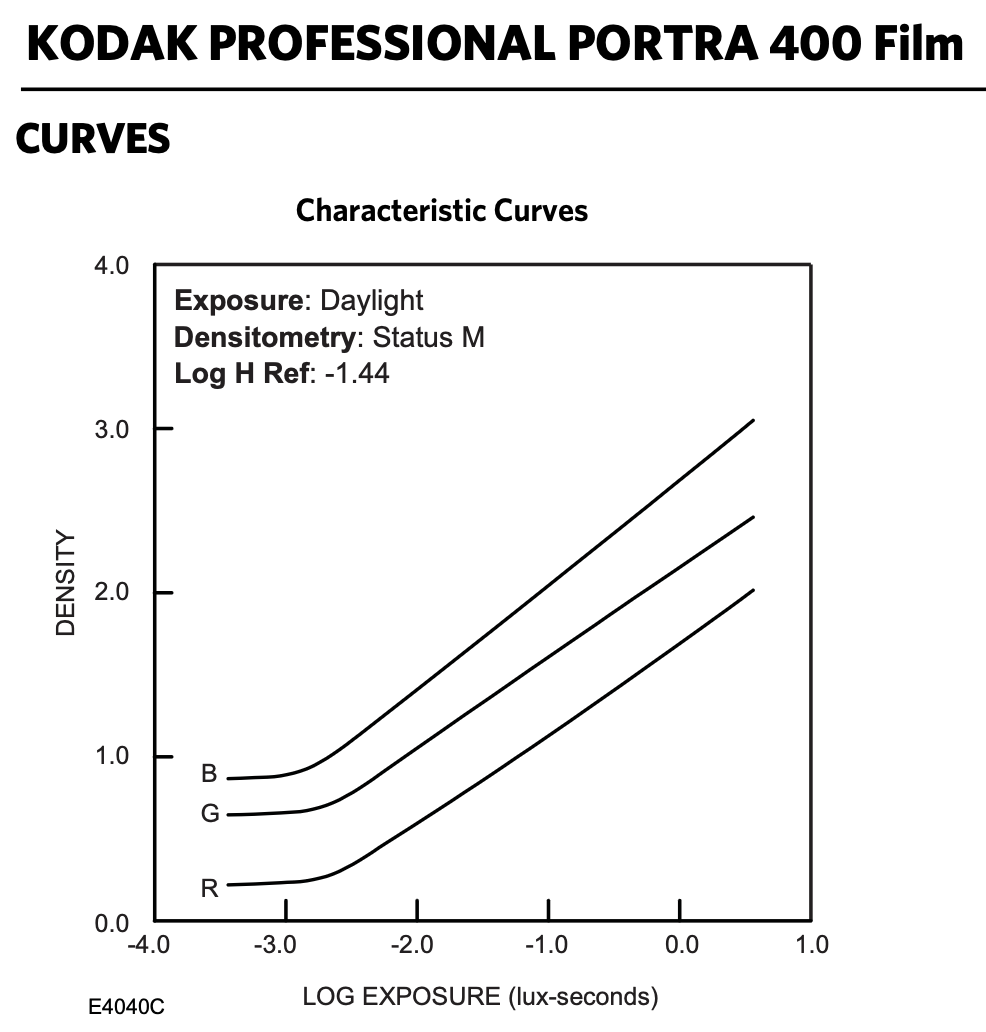

Characteristic curves for Kodak Portra 400 shown for direct comparison to the earlier sensitometric chart. When read against the Vision3 ECN-2 chart, the steeper contrast and earlier shoulder illustrate Portra’s design as a visually complete C-41 still-photography negative rather than a grading-first capture medium.

What the datasheets actually tell you

Comparing a C-41 datasheet with a motion-picture colour negative datasheet makes these differences explicit. Motion-picture negatives are specified with lower contrast indices and broader exposure latitude, reflecting their role as grading negatives. Their characteristic curves emphasise extended straight-line regions and gentler shoulder behaviour. Colour separation data assumes downstream colour timing rather than immediate neutrality.

C-41 datasheets prioritise higher native contrast and visually complete reproduction within standardised printing or scanning conditions. Each system is optimised for a different pipeline. ECN-2 is designed for capture and grading. C-41 is designed for capture and delivery.

The numbers formalise what photographers observe in practice. Fundamentally, the choice of C-41 and ECN-2 film is deeper than it first appears, and using remjet removed film does not mean that it has become a C-41 film.

Why choosing ECN-2 also means choosing the right lab

Choosing ECN-2 is not only a choice of film. It is a choice of workflow. Its advantages only materialise when exposure, development, and scanning are aligned. The negative assumes a lab environment capable of respecting its design.

ECN-2 is not flatter than C-41 in any meaningful sense. It is incomplete by design. The process deliberately withholds contrast and colour decisions so that they remain available to be made later, without penalty. Responsibility is shifted away from chemistry as a corrective mechanism and placed squarely on lighting, exposure discipline, and density-aware scanning.

Development and scanning in an ECN-2 workflow are not independent services. Together they define the physical and digital state of the negative: what information is preserved, how it is encoded, and what latitude remains accessible. If that stage is mishandled, no amount of post-processing can restore what was lost.

Post-processing with a digital solution is therefore not a rescue step. It is in the Kodak documentation that post processing is required to complete the negative. It is the final act of authorship. It is where contrast is introduced deliberately, colour relationships are resolved intentionally, and tonal structure is completed in line with the original lighting and exposure decisions. ECN-2 supports this because the negative arrives at that stage intact, neutral, and information-dense.

ECN-2 makes meaningful digital post-processing possible. The system only functions as intended when every stage—from lighting through to final grading—is treated as a single, continuous chain of decisions rather than a sequence of compensations.

ECN-2 film is developed and scanned in-house at Liquid Light Lab using a density-aware, non-normalised workflow consistent with the system described above. That is not a value proposition. It is the requirement imposed by the medium itself.

By Martin Brown | Liquid Light Whisperer

All images were taken from the official Kodak documentation for Vision3 250D, Portra 400 and ECN-2 scanning.

Technical source documentation

Kodak Vision3 Technical Data (PDF)

Kodak Scanning Recommendations for Extended Dynamic Range Films (PDF)

Kodak Portra 400 Technical Data (PDF)