The AGO Film Processor – A Modern Workhorse for Analogue Photographers

I process a lot of film on the road and at home—black & white in 510 Pyro, plus ECN-2 and C-41 when color calls. The AGO Film Processor has earned a permanent place in these situations because it does the two things that matter most for repeatable results: it keeps agitation perfectly even and it compensates for temperature drift in real time. It isn’t a heater or a water-bath system; you still start at the right temperature. But once you do, AGO’s time/temperature engine quietly corrects for cooling or warming so you get consistent negatives without babysitting the tank.

It isn’t flawless—my drive coupler came loose early on and needed Gorilla Glue—and the menuing will feel fiddly if you don’t like tech. But judged on images, economy, and day-to-day reliability, it’s the best compact processor I’ve used.

Before we get into it: This is not a sponsored review, and I have no affiliation with Vintage Visual who make the AGO film processor.

What the AGO Is (and Isn’t)

Form factor: A compact, motorized base that your Patterson tank docks into horizontally. It rotates the tank for constant, even agitation and shows a live temperature read-out with automatic time compensation. It docks with Paterson Tanks only.

Your job: Mix chemistry, hit the starting temp, load reels, pour on cue, and let AGO run the cycle.

Not a heater: There’s no active heating. Start ECN-2/C-41 at spec (e.g., 41 °C/38 °C) and let AGO’s compensation manage the natural cooling curve.

Where it shines: Repeatability across long sessions, multi-roll runs, and chemistry that benefits from constant rotary agitation (Pyro included when you dial the times).

Temperature Drift Is Real. AGO Levels It Out.

At home we work in real rooms: taps, drafts, and countertops. In an uninsulated tank the working solution loses heat steadily—fast enough to matter over a 5–8 minute developer. Constant hand-timing and frantic thermometer checks become overbearing.

AGO’s trick: it monitors the working temperature and automatically stretches or shortens development time to keep the effective process at your programmed spec. If you began B&W at 20 °C and the chemistry slides to 22–23 °C or downwards during the run (you’ll see it on the display), AGO quietly offsets the minutes/seconds so density and contrast land where you intended. With ECN-2 and C-41, as long as your starting bath is correct, the machine tracks the inevitable drop and corrects in flight. You get the look you want and expect—without recalculating mid-pour.

Custom Programs: Your Process, Memorized

The AGO’s Custom menu is the heart of the machine. I built profiles for:

510 Pyro at my standard and lower-dilution formulas. I built many of these, for a wide variety of B&W film stocks

ECN-2 with my usual pre-bath/rem-jet routine

C-41 for straight color

Each program stores step order, target temps, times, and agitation—so you can run the exact same sequence tomorrow or six months from now. Programming is menu-driven: not difficult if you’re comfortable with devices, but the UX is utility first rather than handholding. Once saved, it’s as simple as select → pour → watch the screen.

How It Handles Pyro Without Drama

Pyro developers reward consistency. With 510 Pyro’s syrup-thick concentrate (micro-dosed via syringe) and long working times, slight temperature drift can tilt highlight separation or overall contrast.

Constant rotary agitation with AGO yields even staining and clean edges.

The compensation model keeps your effective time stable as chemistry moves around room temperature.

Lower-dilution variants are easy to store as separate programs—no mental mathematics mid-session.

Image: My Custom list—510 Pyro, ECN-2, C-41, film-specific tweaks—ready to run on repeat.

ECN-2 and C-41: Precision Without the Water Bath

Color is where AGO becomes addictive. Traditional home color means chasing the thermometer and/or building a water bath. AGO doesn’t let you skip the water heat bath to get your chemicals to temperature, but once you pour, you get extremely tight control:

Hit start-temp (mix above spec, then cool down to target).

Let AGO track the cooling curve and auto-correct the dev time.

Keep your stop/fix/rinse steps consistent with saved programs.

Rem-jet note: AGO doesn’t change rem-jet removal—stick to your pre-bath/wipe routine and you’re fine.

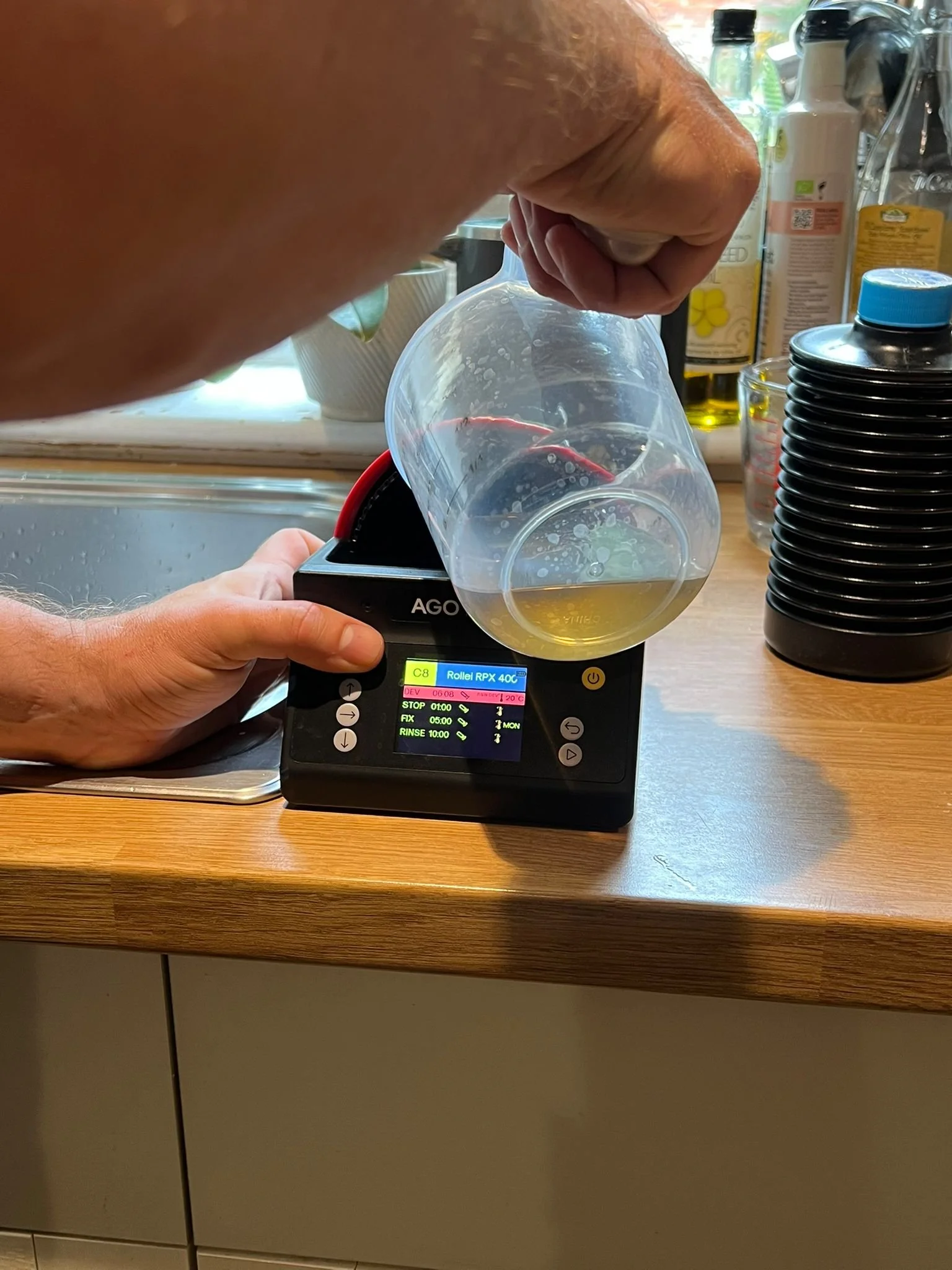

Images: Start at spec and let AGO carry the timing. From chemicals in, to rinse, to negatives coming out.

Chemical Economy: Real Savings Over Inversion

Rotary systems typically need less working solution than inversion tanks, and agitation is more efficient. In practice that means:

ECN-2/C-41: Fewer liters consumed across a 10–20 roll run; replenishment stretches further because agitation is consistent and you’re not overfilling for headroom.

510 Pyro: Lower-dilution runs stay even and repeatable with smaller volumes.

Less waste between steps thanks to predictable cycle times and pour cues.

Over a month of mixed B&W and color, those small efficiencies add up to very real cost-per-roll reductions.

The Workflow I Now Use (Step-By-Step)

Load: Film onto reels in the bag.

Pre-wet / Pre-bath (as needed): Especially for ECN-2/rem-jet.

Developer: Pour when AGO prompts. Watch live temp and remaining time; compensation auto-adjusts.

Stop → Fix → Wash: Each step timed and displayed.

Final wetting agent: (Photo-Flo etc.)

Dry: Hang your negatives in a dust free area.

Results: What the Negatives Say

B&W (510 Pyro): Smooth highlight roll-off, clean mid-tones, and repeatable micro-contrast. Stain is even across the strip, no surge marks.

ECN-2/C-41: Neutral, lab-like consistency when scanned; no temperature-drift surprises in the shadows or skin tones.

Multi-roll loads: Edge-to-edge uniformity—across three 35 mm rolls or two 120s—feels JOBO-level without the footprint.

Build, Reliability & the One Big Gripe

Early in testing the rotating end/coupler on my unit popped off. It was aggravating, especially at this price point. I fixed it with Gorilla Glue and it’s held, but I’d prefer a metal coupler or a mechanically keyed design from the factory.

The only fail: the coupler worked loose. Glue fixed it; a metal part would prevent it.

Otherwise the unit has taken splashes, long sessions, and the usual home-lab bangs without a hiccup. Keep a towel by the display and don’t pour like a maniac; you’ll be fine. I keep kitchen towel to hand around the AGO to stop the inevitable splashes in between the different development phases.

Usability & Programming Notes (Read This Before You Buy)

Menus: Functional and consistent once you learn the rhythm; not “pretty,” especially when updating firmware or adding dev profiles.

Programming: Easy if you’re comfortable with devices. If not, set aside 20–30 minutes to build your first profiles and test with water.

Audible cues: Helpful for pour/change steps—no scrambling with a phone timer.

Space: Small footprint; sits happily by a kitchen sink.

Noise: A steady, low hum—conversation-friendly.

Tips for Better Runs (B&W, ECN-2, C-41)

Pre-heat the tank (rinse with tempered water) so you don’t give heat away at the first pour.

Over-mix slightly warm chemistry, then cool down to target—more predictable than trying to warm up.

Save separate profiles for push/pull variants and for different 510 Pyro dilutions—don’t edit on the fly.

Mind your volumes: Rotary agitation doesn’t need inversion headroom; use the minimums your tank specifies for even coverage.

Pyro safety: Nitrile gloves, goggles, zero splashing. The closed tank helps—respect the chemistry anyway

Who It’s For / Not For

Buy it if you want:

Lab-like consistency without a full JOBO line.

Color at home minus the water-bath choreography.

Lower chemistry use and repeatable automation for multi-roll sessions.

The ability to save exact recipes and run them weeks later without thinking.

Skip it if you expect:

Integrated heating/water-bath control (this isn’t that).

A hand-holding touchscreen UI.

Zero tinkering. It’s close—but not appliance-grade in that sense

Pros & Cons (Condensed)

Pros

Excellent time/temperature compensation—the killer feature

Constant rotary agitation = even development, fewer artifacts

Custom programs for 510 Pyro, ECN-2, C-41, push/pull profiles

Chemical savings vs inversion methods

Compact footprint, clear prompts, predictable cycles

Cons

My unit’s drive coupler failed and needed glue (unhappy about this)

Menus are utilitarian; non-technical users may find setup fiddly

No active heating—you must nail the start temperature yourself

Verdict

The AGO Film Processor is excellent where it counts: negatives. The compensation engine removes the anxious part of home processing, the rotary agitation makes results look lab-clean, and the ability to store complete programs means I can switch from 510 Pyro to ECN-2 or C-41 without re-thinking the entire workflow. It saves chemistry and time every week.

I’m still annoyed that the coupler came off early on—and I’d love to see that part redesigned in metal. The UI could be friendlier. But those are compromises I can live with for what the AGO delivers: repeatable, economical, professional-quality runs for up to 8 rolls of film at a time.

If you care about consistency more than ceremony, this is the right machine.

If you’re still on the fence, Vintage Visual, the makers of the AGO, have been attending events like the Photo Show. They’re approachable, great to talk to, and I’m sure you’ll be able to make a decision if this is for you if you speak to them.

Follow Vintage Visual over at Instagram

All images in this article were developed in my home using the AGO.

All images in this article were developed and scanned in-house and UK-wide lab at Liquid Light Lab, our dedicated 35 mm film development and studio based in Leamington Spa. Send in your film and you’ll get exceptional results, up to 60MP TIFF and JPEG scans, and rare pyrogallol for exceptional black and white images.

By Martin Brown | Liquid Light Whisperer